This is a SEO version of HAI_Price_List_2010. Click here to view full version

« Previous Page Table of Contents Next Page »Quality and Environmental Aspects of Process Solvents

Proper composition of slurry and pack-ing solvents is vital to the whole process. Our solvent purification equipment and procedures allow us to address all of the solvent requirements for production and quality control. Not only does this investment permit us to use the highest purity solvents available, it also eliminates much of the expensive and environment-polluting solvent disposal practice char-acteristically found in today’s chemical industry.

Unique Bonded Phase Synthesis

Chemists at Higgins Analytical have been producing bonded phases since 1979. During this long experience, we have pioneered many technologies long before they were “discovered” by others with a bigger marketing clout. Higgins Analytical’s introduction of a “No

Requirement for TFA” HPLC column in early 1997 is just one example of our vanguard approach to this field.

Computer Aided Drawings and Numerical Control Machinery

Key to reinforcing our ability to provide the highest performance-to-price ratio products available in the separations consumables industry has been our investment in computer aided design (CAD) technology and computer numerically controlled (CNC) machinery. SolidWorks™ software is used by our engineers which permits us to design HPLC hardware and see it in its

P ROCE S S AND P RODUCT CONTROL

3

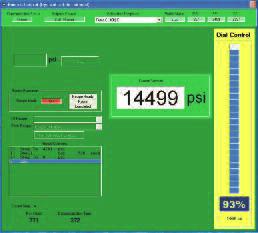

changed without an exper t supervisor’s intervention.When new processes for new products are developed or optimization is required for an existing method, a complete audit trail is created for every condition change that is made. The packing pumps operate with PID (proportional integral/derivative) controllers allowing for control flow rate,

rather than pressure, throughout the packing process.This is a very impor tant point. Common folklore is that it takes high pressure to pack an HPLC column. Actually, pressure is only the result of a

complex two phase (liquid/solid) flow. This flow, not pressure, is what produces a packed bed.The “pressures” used by many column manufacturers are the result of flow rates that approach the velocities that will produce a “fluidized bed” during certain phases of the packing process, not exactly a condition that will produce a stable, optimally packed column. In addition to being able to control our equipment digitally, we are able to data log the actual conditions as well.

Our unique and highly automated column packing process is based on a closed, continuous flow system employing recoverable, unreactive, and safe fluids. And the best par t about it is that it enables Higgins Analytical to manufacture a wide variety of HPLC columns with unrivaled efficiency.

assembled 3D form before we manufac-ture it. Dedicated tooling and secure backups of machine code assure fast setups and consistant high quality production of all the stainless steel and plastic components in each product line.

Our product development, manufac-turing, and testing processes strictly follow a systematic and well documented cycle.

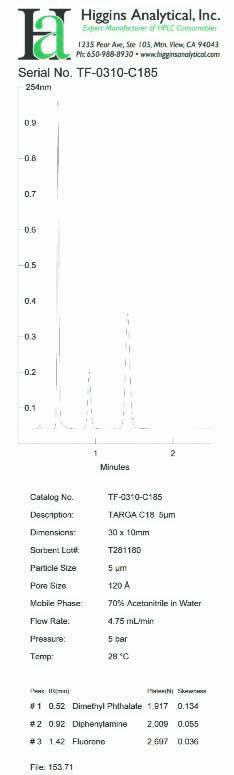

A Certificate of Analysis, like the one below for a 3cm x 10mm cartridge, accompanies each HPLC Column and Cartridge we manufacture

Note: This high performance cartridge is typically used as a guard column.

This is a SEO version of HAI_Price_List_2010. Click here to view full version

« Previous Page Table of Contents Next Page »