|

|||||||||

Comments

To

remove a blockage, use the following procedures. After each step, test

to see if flow has been restored before proceeding to the next step.

1) Backflush the injector in both the LOAD and INJECT positions by disconnecting

the column and connecting the pump to port #3. Use the highest flow rate

achievable by the pump.

2) Clean the stator, loop, and/or vent tubes for at least five minutes

with an ultrasonic cleaner using a variety of solvents.

3) Use a .010 in OD or smaller wire to clean out the stator face assembly

holes.

4) Clean out the rotor seal channels, being careful not to scratch the

polished surface.

5) Replace the parts. If crystallized buffer salts have caused blockage,

prevent future problems by periodically flushing the injector, especially

prior to shutting down the system. See Appendix E

for the flushing procedure.

Symptom #13 (Continued)

Cause B

The column or column connecting tube (A) is plugged. The injector is OK.Solution

Replace or clean them.Cause C

The pump tube (B) is plugged, or the pump is malfunctioning. The injector is OK.Solution

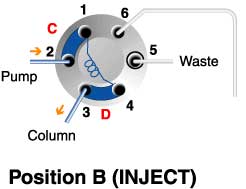

Troubleshoot the pump. Check the pump tube (B) in case it is plugged.Cause D

Particles are blocking port #1, port #2, or the rotor seal groove (C).Solution

Clean them. See comments for a procedure.Cause E

Particles are blocking the loop.Solution

Clean or replace it. See comments for a procedure.Cause F

Particles are blocking port #3, port #4 , or the rotor seal groove (D).Solution

Clean them. See comments for a procedure.

Fig. 41. Flow diagram of the injector in the INJECT position.

© 2000 Rheodyne All rights reserved