|

|||||||||

Comments

Some

injectors, like the Model 7725, have a patented continuous-flow design.

When turning the handle, a passageway in the stator face makes the new

flow connections before the old connections break ("make-before-break"

design). There is no momentary interruption of flow.

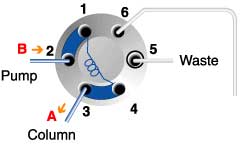

Other injectors, like the Model 7125, interrupt the flow during movement of the handle from one position to the other. Fig. 40 shows such a model. When the rotor seal is rotated back to the LOAD position (clockwise since this is a view from the rear), you can see for a time that the pump is not connected to either port #1 or port #3. This causes a transient: in the pump line the pressure rises and the flow stops, in the column line the pressure falls and the flow stops. The magnitude of these effects increases when the handle is turned slowly, the flow rate is high, or the pumping system has a low compliance. Usually the transient has no effect on the system, but when using flow sensitive detectors, fragile columns, or pumps that are disturbed by flow or pressure changes, injectors having Rheodyne’s continuous flow design may be preferred.

Symptom #13

The system pressure is unusually high, either constantly or only during movement of the handle:

- If the pressure increases when the handle is turned, then returns to normal, see Cause A.

- If the

pressure remains high in either the LOAD or INJECT position,

Locate the blockage, with the handle in the INJECT position, by observing the pressure under the following conditions. Note Fig. 39 and Fig. 40.

- Disconnect the column connecting tube at port #3 (A). If pressure returns to normal — about zero psi, depending on the flow rate, connecting tubing, and sample loop — see Cause B, otherwise,

- Disconnect the pump connecting tube at port #2 (B). If pressure remains high see Cause C, otherwise,

- Reconnect the pump. Remove the loop. If pressure remains high see Cause D, otherwise,

- Reconnect the loop only at port #1. If pressure remains high see Cause E, otherwise see Cause F.

Cause A

The interruption of flow, which occurs with some models (see comments) when the handle is turned, causes a momentary increase in backpressure.Solution

Turn the handle faster.Fig. 39. Flow diagram of the injector in the INJECT position.

Fig. 40. Flow diagram of Rheodyne’s patented MBB™ design.

© 2000 Rheodyne All rights reserved