138

Valves

Application Note

Application Note

Application Notes

Fluidic Movement in Tubes

Q:

“Why can I load only up to half of the volume of the loop

in partial-flling method?”

A:

Sample occupies 2 µL of loop for every 1 µL loaded from the syringe.

For example, 10 µL of sample spreads out over the entire length of a

20 µL loop. Any additional sample loaded will overfow the end of the

loop and exit out to waste. Reproducibility is poor because the volume

of sample in the loop is different from the known volume originally

loaded by your syringe.

Fluid spreads in a parabolic shape through a tube instead of moving in one

plug because the velocity is different at the center of the tube than at the

walls. The velocity at the center of the tube is twice the average velocity,

and near the wall the velocity is almost zero, creating a parabolic shape. This

fuidic movement is called laminar fow. See Figure 1.

In dual mode injectors (see “Sample Loop Loading” Application Note on page 131)

the sample from the syringe needle loads directly into the sample loop. The sample

volume is known since there is

no sample waste. The laminar

fow phenomenon accounts for

the shape of the plot as shown in

Figure 2. Note that the plot has

three regions:

a) Partial-Filling Region. When

the volume dispensed is less than

half the loop volume, the curve is

linear. Sample has not reached the

end of the loop. Within this region,

performance depends on the

syringe and operator.

b) Nonlinear Region. When the

volume dispensed is between

half the loop volume and about

two loop volumes, the curve is

nonlinear. Sample is lost from the

loop, so reproducibility is poor. If

you dispense a volume equal to

the loop size, you are in this region

of poor performance.

c) Complete-Filling Region. When the volume of sample dispensed is several loop

volumes, the loop contains only pure sample, undiluted by residual mobile phase.

Within this region, reproducibility is highest.

In the single mode injectors the sample must pass through a connecting passage

before it reaches the sample loop. Since some of the sample dispensed from the

syringe remains in the connecting passageway, an unknown amount enters the

sample loop. Therefore, single mode injectors achieve high reproducibility only by

using the complete-flling method.

Sample

Flow

Tube Wall

Mobile Phase

Figure 1 Schematic of sample fow through mobile phase between tubing walls

Sample Dispensed (loop volumes)

1 2 3 4

40 80

constant

Figure 2 Sample mass (observed peak area)

vs. volume of sample dispensed from the

syringe, in units of loop volumes, injected

onto the column from a Rheodyne

®

dual

mode injector such as model 7725

How to Find and Fix Common Sample Injector Leaks

Leaks cause valuable sample loss. Nobody wants that. The key to the valve

holding pressure is the integrity of the sealing surfaces. If there is a scratch

on the sealing surface, or the needle seal in the rotor seal is damaged, a

leak may appear. It is also important to realize what appears to be a leak

can instead be a result of siphoning. The following are the three most

common situations in which fuid leaks occur.

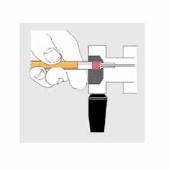

1. If fuid leaks out of the needle

port only while loading the loop

(i.e., while pushing down on the

plunger of the syringe), the problem

is most likely that the needle seal or

the needle port ftting in the loop fller

port is not gripping the syringe needle

tightly enough. Tighten the needle

seal grip by pushing with the eraser

end of the pencil on the needle port

(See Figure 1). The tightening reduces

the hole diameter of the needle seal

and port ftting.

2. If fuid leaks continuously from the needle port or vent lines and/or from

the stator-to-stator ring interface, replace the rotor seal and/or stator face

assembly. Scratches on the rotor seal or cracks in the stator face assembly

allow mobile phase to escape and cause cross port leakage. Genuine

Rheodyne replacement rotor seals are listed on page 134.

3. If fuid leaks from the needle port and/or vent lines but eventually stops,

the cause is most likely siphoning and not a leak. Siphoning occurs if the

vent lines are lower or higher than the needle port. Adjust the vent line(s) so

that the outlet is at the same horizontal level as the needle port to prevent

siphoning. (See Figure 2).

For other leakage or injection troubleshooting, refer to the Rheodyne

Troubleshooting Guide for HPLC Injection Problems. You may download the

Guide from the Rheodyne web site: www.idex-hs.com under Support.

Figure 1 To reform the needle seal,

push the eraser end of a pencil

against the needle port

Figure 2 Needle port level compared to the level of vent line outlet:

(A) siphoning occurs when the vent line outlet is above the needle port level

(B) siphoning does not occur if the vent line outlet is the same horizontal level

as the needle port

FOR ORDERING & DISTRIBUTOR INFORMATION +1 800 426 0191 • +1 360 679 2528 • www.idex-hs.com