General Purpose, Low Pressure, and SPME Microseals

Wiper rib

Spring

Injection port

septum cup

Duckbill

Valve

O-rings make sliding seal around needle

O-rings

Needle forces duckbill valve open

Microseal nut

Merlin Microseal

Syringe needle

Microseal Injection Sequence

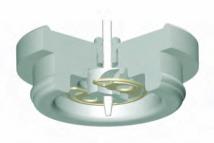

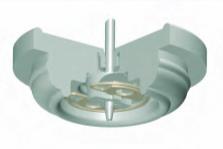

Microseal Cut-Away Views

General Purpose and SPME Microseals

Dust wiper rib

O-rings seal needle

during injection

Duckbill opens easily,

seals reliably

Spring

O-rings

Duckbill

Spring

Low Pressure Microseal

Introduction

The Merlin Microseal

TM

is a microvalve alternative to the

conventional silicone rubber septa used in gas chromatography

(GC). Its unique design gives it high pressure capability and

resistance to wear which results in long life and excellent

chromatographic performance. The Microseal is available in three

versions for all major GC manufacturers’ instruments.

How the Microseal Works

A GC injection port septum performs two discrete functions.

It seals the port while the syringe needle is inserted and also

while the needle is not inserted. The Microseal is distinct from

traditional septa in that the Microseal has two independent sealing

mechanisms to perform these functions. O-rings seal the syringe

needle during sample injection. Aduckbill valve seals the injection

port during analysis, but allows the needle to slide through without

damage. In contrast, a conventional septum is repeatedly pierced

by the syringe needle and eventually leaks or sheds septum

particles into the injection port liner.

Because the two seals perform separate, individual functions

and are only slightly distorted in operation rather than being

pierced, the Microseal can be made from a high-temperature,

wear-resistant fluorocarbon elastomer. In combination with the

cone-tipped needle, this means the Microseal will not shed pieces

into the injection port, even after thousands of injections.

The cut-away views show the location of the individual seals

and the diagram at the lower right illustrates the following

sequence of Microseal functions.

1. Pressure in the injection port, aided by a stainless steel

spring, squeezes the duckbill closed and maintains a tight

seal on the port. Higher pressures seal it more tightly.

2. As the syringe needle enters the Microseal, the wiper rib

removes any particles adhering to the needle.

3. The O-rings then make a sliding seal around the needle.

4. As the needle penetrates further, the tip pushes the duckbill

valve open and slides into the injection port. The O-rings

maintain the seal around the needle.

5. As the needle is withdrawn from the Microseal after sample

injection, the spring pushes the duckbill valve closed before

the needle leaves the O-rings. The port remains sealed

during the injection process.

Choosing a Microseal

Three versions of the Microseal are available.

General Purpose Microseal (P/N 410)

- Formerly known as the

“High Pressure Microseal,” this Microseal is recommended for

use in most GC applications with injection port pressures between

3 and 100 psi (20 - 690 Kpa). The General Purpose Microseal is

the best choice for most GC applications.

Special purpose Microseals are also available for for low inlet

system pressures and solid phase microextraction (SPME).

Low Pressure Microseal (P/N 310)

- Formerly known as the

“Original Microseal,” this is recommended for injection port

pressures between 1 and 45 psi (7 -310 Kpa). Particularly useful

for fast GC/MS applications with 530 micron columns. The Low

Pressure Microseal is made from a softer elastomer and does not

have the needle wiping rib.

SPME Microseal (P/N 21-01)

- This Microseal was developed

with a stiffer elastomer specifically for 23 gauge SPME probes,

which have a square end instead of the cone shaped tip

characteristic of syringe needles. These probes can cause additional

wear and this version provides extended lifetime for SPME.

Microseal User Manual