|

|||||||||

Comments

Cleaning

the loop or stator passages can usually be achieved by immersing the individual

parts for at least five minutes in an ultrasonic cleaner using a variety

of solvents.

Backflushing ports with the pump set at high flow rate is sometimes effective in cleaning certain passages.

A .25 mm (.010 in) OD or smaller wire can be used to remove particles that do not dissolve.

See also Symptom #9 for related problems.

Symptom #12 (Continued)

Cause C

Particles are blocking the loop.Solution

Clean or replace the loop.Cause D

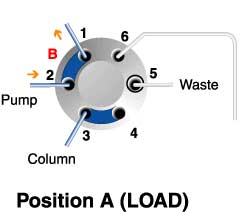

Particles are blocking the stator, stator face assembly, and rotor seal passage (B) associated with port #1 (see Fig. 37).

Fig. 37. Detailed view of passageways where particles can obstruct flow.

Solution

Clean these passages. Try using the pump at high flow rate with the loop removed and the handle in the INJECT position (see Fig. 38). In the future, you may need to flush these passageways periodically, especially if the mobile phase or sample contain buffer salts which can crystalize when the solvent evaporates (see comments).

Fig. 38. Flushing out the passageways associated with port #1, in the INJECT position.

© 2000 Rheodyne All rights reserved