|

|||||||||

Comments

The

contribution to non- reproducibility made by the non-injector parts of

the system can be determined by making a series of injections with the

loop completely full of sample each time an injection is made. Under these

conditions the injector will transfer sample to the column with a volumetric

precision of about 0.1%. The amount by which the observed precision of

areas and heights is larger is the amount due to the non-injector parts

of the system.

To make such a "completely full" injection: Load the loop with ten loop volumes to displace all air and mobile phase. Use the same rate of loading each time. Keep the syringe in the port while turning to INJECT (standard procedure). Inject immediately after loading to ensure that a leaking rotor seal, should it exist, does not have time to displace sample from the loop. During loading, observe that no more than 10% of the sample flows back out the needle port. None should flow out if the needle seal is functioning properly, but this test allows for even a malfunctioning seal. The 10% limit means that at least nine loop volumes will pass through the loop — enough to produce high precision.

Rheodyne RheBuild™ Kits are available for all injectors. Kits contain only genuine Rheodyne parts together with tools and instructions.

Symptom #7 (Continued)

Cause D

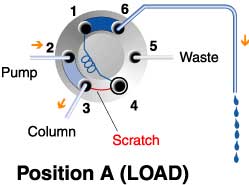

A cross-port scratch on the rotor seal allows mobile phase to leak into the loop while in the LOAD position, displacing sample (see Fig. 26). To confirm: Load the loop with five loop volumes of sample and inject immediately. This makes an accurate injection of a complete loop volume. Observe the peaks. Load the loop again, but delay turning to INJECT, allowing time for any leakage into the loop to displace sample. Inject and observe the peaks. Smaller peaks indicate leakage. The longer the delay, the smaller the peaks.Solution

Replace the rotor seal as in Symptom #3. Examine the ceramic surface of the stator face assembly and replace the assembly if it is chipped, cracked, or if any of the six holes are blocked (see comments).

Fig. 26. View of the rotor seal with the injector in the LOAD position. A scratch between ports 3 and 4 can displace sample from the loop.

Cause E

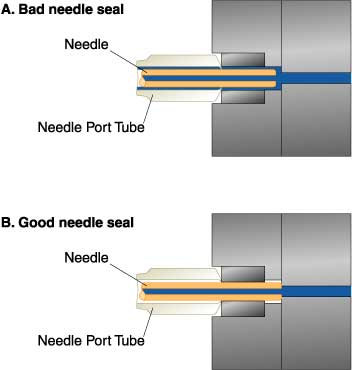

The problem may not be the injector. Check to see if the needle seal is working. When it is loose, not all of the sample dispensed from the syringe enters the loop (see Fig. 27). You can discover if the seal is leaking by using the procedures in Symptom #1. See also Symptom #9 and the comments at the bottom of this page.Solution

Re-form the seal if it is leaking. Make sure that you are using the proper syringe needle.

Fig. 27. With a bad needle seal (A) sample leaks around the needle seal and into the needle port. With a good needle seal (B) there is no leakage.

© 2000 Rheodyne All rights reserved