|

|||||||||

Comments

To

flush the needle port and fill it: Use about 1 mL of mobile phase. Use

a Needle Port Cleaner

(Rheodyne Part Number 7125-054) attached to a luer tip syringe. Flush

only when the handle is in the INJECT position, so flow goes directly

out vent tube #5 and bypasses the loop. This procedure cleans the entire

length of the port — guide, tube, and needle seal-filling it with

liquid. If you have no cleaner, use a luer tip syringe. See the illustration

with Fig. 18.

Mobile phase and excess sample displaced from the loop during loading exits via vent tube #6. It can easily become plugged with buffer salt crystals. If this happens frequently, you should periodically flush the injector in the LOAD position to prevent build up of crystals.

The syringe should be left in the needle port until after injection, otherwise some or all of the sample may siphon out of the loop. See also Symptom #12 for related problems.

Symptom #9

All peaks are very small, or no peaks are observed.While turning the handle, observe the shaft to which it is attached:

- If the

shaft does not rotate, see Cause A.

- If the

shaft rotates a full 60¡:

In the INJECT position, fill the needle port by flushing (see comments and Fig. 29). Turn to LOAD and insert the syringe (a little solvent will appear at the port). Load sample while observing the port and vent tube #6. - If solvent comes out the needle port while loading, but none or very little comes out vent tube #6, sample is not entering the loop. See Cause B.

- If solvent does not come out the needle port, but does come out vent tube #6, sample is entering the loop. See Cause C.

Fig. 29. Fill the needle port with solvent using the needle port cleaner.

Cause A

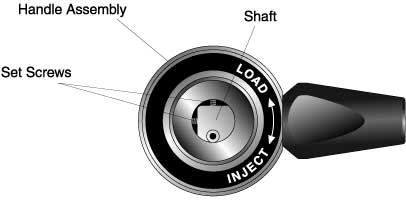

The knob assembly is slipping on the shaft.Solution

Tighten the two set screws against the flats on the shaft (see Fig. 30). The third screw hole in the knob allows repositioning on the shaft; use only two screws in any one position.

Fig. 30. The set screws on the knob assembly need to be tightened on the flats of the shaft.

Cause B

The needle seal is malfunctioning (see Fig. 29) and/or vent tube #6 is plugged.Solution

Confirm you are using the proper needle. Clean vent tube #6 if it is plugged. Adjust the needle seal per the tests in Symptom #1.

© 2000 Rheodyne All rights reserved