|

|||||||||

Comments

In

Cause A, if cleaning the tube does not solve the problem,

clean port #6.

The normal procedure for flushing the needle port is: Use about 1 mL of mobile phase. Use a Needle Port Cleaner (Rheodyne Part Number 7125-054). Flush only when the handle is in the INJECT position, so flow goes directly out vent #5 and bypasses the loop. If you have no cleaner, use a luer tip syringe. See Fig. 18 in Symptom #5.

In solving Causes A and B, make an additional flush when the handle is in LOAD in order to flush the passages of ports #4 and #6, and vent tube #6. If the purpose of flushing is to remove buffer salts, do it with water not organic solvents.

In routine operation, remove the syringe after turning to INJECT. However, keep the handle in this position so the loop is continuously flushed with mobile phase. We recommend keeping the needle port filled with fluid by flushing every ten or twenty injections. Flush just before the next analysis.

Backflushing ports with the pump set at high flow rate is sometimes effective in cleaning certain passages.

See also Symptom #9 for related problems.

Symptom #12

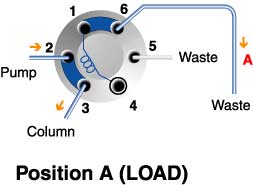

The sample loop cannot be loaded or offers excessive resistance when loading sample.Locate the blockage by attempting to load sample under the following conditions (use Fig. 35 as your guide):

- Remove vent tube #6 (A). If the resistance is gone, see Cause A, otherwise,

- Remove the loop. If resistance is still there, see Cause B, otherwise,

- Reconnect the loop only at port #4. If resistance returns, see Cause C, otherwise,

- Reconnect

the loop at both port #1 and #4. If resistance returns, see Cause

D.

Fig. 35. Flow diagram of the injector in the LOAD position.

Cause A

Particles are blocking vent tube #6 (A).Solution

Remove and clean the vent tube. In the future, flush this tube periodically, especially if the mobile phase or sample contain buffer salts which can crystalize when the solvent evaporates (see comments).

Cause B

Particles are blocking the needle seal or the stator passages associated with port #4 (see Fig. 36).Solution

In LOAD, with the loop removed, flush the needle port two or three times using the needle port cleaner (see comments).

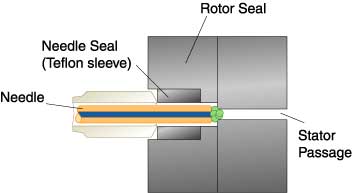

Fig. 36. Enlarged view of the needle seal and stator face assembly showing particles (green) blocking the passage.

© 2000 Rheodyne All rights reserved